SAMPLE-B

| Model: | SAMPLE-b |

| Place of Origin: | Zhejiang,China (Mainland) |

| Brand Name: | Webitelecomms |

| Products name: | cold aisle |

| Material: | SPCC cold rolled steel or EG steel |

| Package:: | assemble or dis-assemble |

| Colour: | black, gery ,white etc |

Product Description

| Payment & Shipping Terms | Supply Capacity | ||

|---|---|---|---|

| Trade Term: | FOB | Production Capacity: | 1000pcs/month |

| Payment Terms: | L/C, T/T | Packing: | cartons, pallet,... |

| MOQ: | 50 Piece/Pieces | Delivery Date: | 35 days |

| Means of Transport: | Land, Ocean, Air | ||

What is Data Center ?

The solution to gather servers and other active equipment and provide a method of cooling and protection.

-----------------------------------------------WebiTelecomms-------------------------------------------

Using Webtelecomms cabinets and components designed for data centres, a complete data centre can easily and efficiently be built. The most commonly used solution in terms of cooling:

=Airflow principle=

Hot / cold aisle

Arranging cabinets into hot / cold aisles is a standard solution for data centres. Cabinets are oriented face to face, while cold air is supplied through perforated tiles in a raised double floor.

Standard ANSI/TIA/EIA-942-A recommends a cold aisle width of 1.2 metres. This is generally the size of two double floor tiles.

Cold air is supplied via perforated tiles at the front of the cabinets which is delivered to each of them by fans.

Cold air is supplied to active elements through doors with 80% perforation. In this case, the double floor is used to deliver cold air and it is necessary that all other openings in the floor, such as the cable entries are covered.

The reason is to maintain static air pressure in the double floor and to minimise cold air loss.

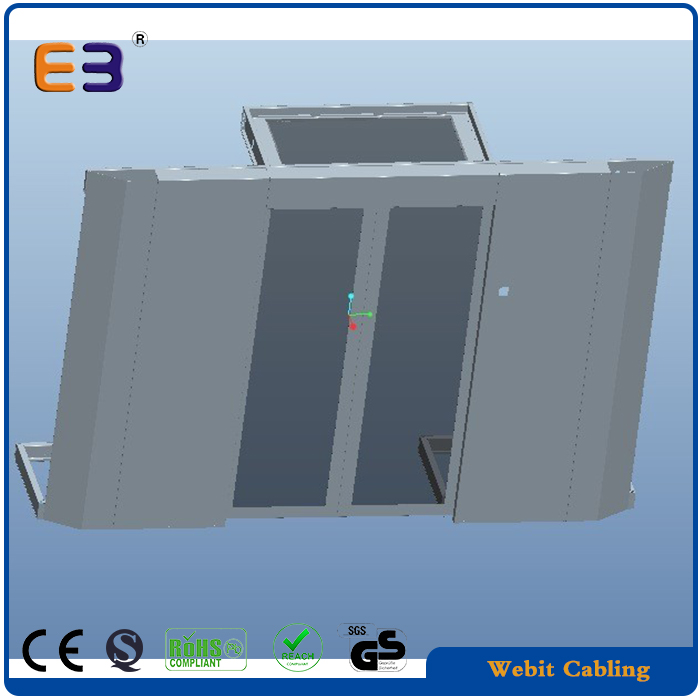

Contained cold aisle

The solution of open hot / cold aisles presents possible shortages in the recirculation of heated air and therefore the risk of creating so called hot-spots - locally overheated areas.

The solution is a contained cold aisle. This is a closed modular expandable system which physically separates the cold air from the exhalation of hot air.

Actually, it creates a separate area for hot and cold air and prevents them from mixing.

Cool air is fed into the closed aisle through perforated tiles of the raised floors or locally using the side cooling units, which are mounted directly in line between the cabinet.

Standard width of the contained cold aisle is 1.2 metres (two floor tiles) or 1.8 m (three floor tiles). At the ends, the aisle also has a glass sliding door.

The use of this solution is becoming standardised and is especially recommended for its cooling capacity and efficiency in achieving the lowest energy consumption of the data centre.

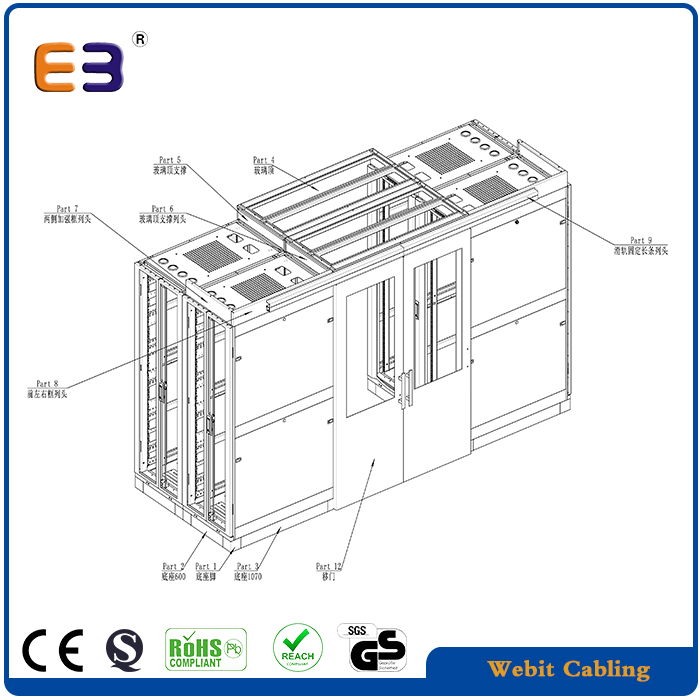

Closed modular solution

A closed modular solution enables maximum energy efficiency and scalability of focus for long-term development of a data centre.

This solution can be designed and manufactured tailored to customer needs.

In one room there can be zones not only with different operating temperatures, but also with different density of the thermal load.

The solution is characterised by a high-IP cabinet. This also protects the installed components from dust and moisture.

Side cooling units are attached directly with the racks to make a closed module with an internal cold zone at the front part of the cabinet and hot zone at the rear of the cabinet.

This solution allows you to combine any number of racks and cooling units in the module.

Our specialists will prepare a proposal for the project to ensure the space capacity required for installation of the equipment and the corresponding power conditioning, including any needed redundancy.

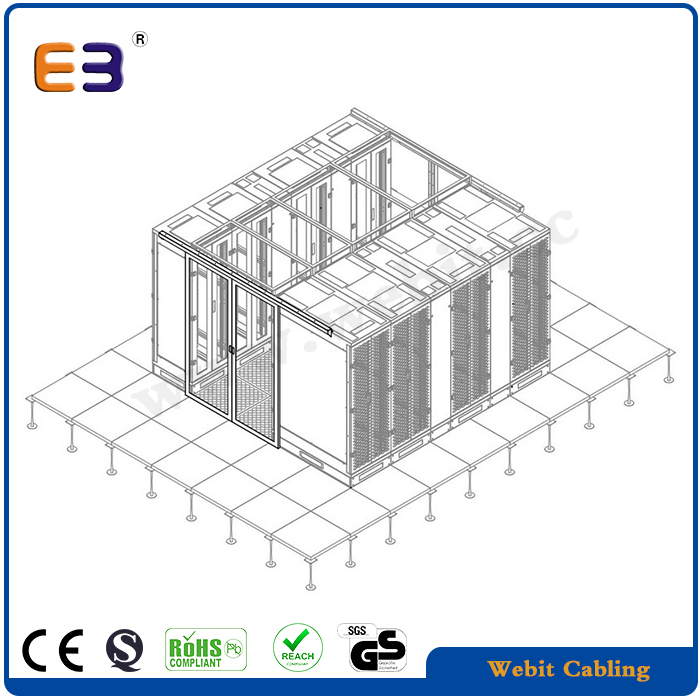

Floor feet

This method increases the efficiency of the cold air through the delivery from double floor to the installed equipment.

The cabinet is installed on the opening in the double floor. A deflector, located at the bottom of the cabinet, directs cool air to its front section.

Cold air in this case is further directed in the front section of the cabinet by the door without perforations, these may be of glass or metal. The hot air is extracted from the rack either by doors with 80% perforation or the cabinet ceiling.

By installing a cool air supply regulator to the bottom of the cabinet the amount of air may be adjusted, or delivery can be completely discontinued when the cabinet is not in use.

The advantage of this cooling method is great flexibility in planning of the room usage. Cabinets installed in hot and cold aisle is not required if the hot and cold air is separated inside the cabinet.

To achieve this it is necessary to install a separating frame inside the cabinets for a strict separation of cold and hot air.

Floor feet with plenum return

A possible disadvantage of cold aisle and cooling supply from the floor and return to the room is that the hot air is brought into the surroundings of the installed equipment.

This does not cause a complication when it is already considered in the data centre design stage.

In certain cases a possible solution is to completely separate the warm air in areas with high thermal loads due to the concentration of the installed equipment.

The solution is to supply cooling air from the room or raised floors and return it to the ceiling.

This is the solution when the hot air does not return into the hall, but is fed to the ceiling or double ceiling.

A rear deflector located in the upper part of the cabinet helps to optimise the flow of hot air into the outlet extension. A large adapter allows the passage of large quantities of air at a relatively low speed.

A cold air intake is on the front door of the cabinet, and hot air is discharged through the outlet extensions to the ceiling / double ceiling above the devices.

Air conditioning units take the hot air from the ceiling, cool it and deliver it back under the raised floor. The air cooling circuit is closed.

This solution provides high efficiency cooling for very large volumes of hot air. Research indicates that this solution can be used to cool up to 30 kW per cabinet.

Data centre design

This critical stage of the data centre building has an indefinite solution. It depends on the cabinet arrangement, distribution of heat load and its size, the choice of thermal scheme (hot / cold aisle, zonal distribution of cold etc.) and many other aspects.

When selecting the most suitable arrangement it is necessary to take into account the type of cooling system (under-floor cooling, In-Row cooling units ...) and with regard to the coolant used, also selecting the outer part of the system.

Choice of the cooling medium must be done with respect to outdoor climatic conditions, the distance of the data centre from the external units and the elevation between them.

Depending on conditions, we can choose water cooling with appropriate addition of antifreeze, or system operating with liquid refrigerant gas.

With regard to safety and redundancy required for service operations it is necessary to design the complete system properly, meaning inside the data centre and on the side of radiators or condensers.

Furthermore, it is necessary to think about the requirements of humgoods_idity control. Humidity less than 30% carries a risk of damage to the installed equipment by static electricity surge; high humidity can lead to condensation.

In our portfolio you will find the cooling systems of leading manufacturers active in this highly specialized field of data centres and telecommunication equipment cooling for many years.

Thanks to the close cooperation and support of their development teams, we can offer proven and guaranteed solutions.

Designing functional, reliable, financially and operationally economical cooling systems for the data centre is not an easy matter and specialists, who will recommend the optimum solution in terms of investment and operating costs, are fully available.

Power distribution units

Equipment installed in data centres often has very high power consumption. Along with the need for a power supply, it also brings the question of the need for metering and remote device control.

Therefore you will find power distribution panels in our range, which not only allow you to switch each device on or off, but also provide information on the temperature and humidity in the cabinet, check the correct

functioning of the condensate drain of the cooling unit, signal an alarm when the cabinet door is open and other conditions that you define.

Any changes can then be reported using the integrated software through a computer network and allow you to oversee the data centre without the physical presence of the operator.

Distribution panels with management systems exist in many different models.

Whether in terms of dimensions, where we offer solutions from the standard 19" panels to large vertical panels designed to house distribution systems, or in terms of different inputs (16A-64A, single-phase / three-phase).

It is possible to choose from many product lines according to the required panel functionality

(measurement of panel as whole unit or measurement of individual outlets, the control panel as a whole or individual outlet switching, additional monitoring functions temperature/ humidity / door contact / water flood sensor).

Contact Now

Contact Now